How do Diamond Blades work?

Diamond blades (and barrels for coring) don't cut - they grind.

And the diamonds do the grinding work!

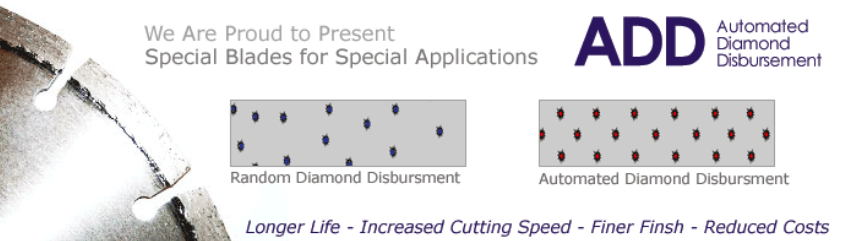

There are diamond crystals exposed on the edges and sides of the segments encased in their "bond" and these crystals do the grinding work as the blade or core barrel rotates.

The bond locks each crystal in place and behind each diamond crystal there is a tail of bond that helps support the diamond segment and lock it in place. The grinding process causes the substance being cut to be converted into a fine powder, while the bond also wears away exposing more diamonds to complete the work.

As the cut material wears away the bond, the diamond crystals crack and fracture into tiny pieces that also assist in the grinding process. Harder materials break down the diamond structure faster, requiring a more concentrated array of diamonds in the bond. This continuous grinding and wearing process continues until the blade is "worn out" although sometimes a small, unusable part of the segments or rim may remain.

Matched to the material

It is important to understand that the diamond blade must be matched to the material for the blade to cut effectively. The diamond type, quality and grit size must be suited for the saw and the material. The bond material must also be matched to the material to be cut. So, a single blade to cut all materials is unachievable.

Undercut protection is usually found on floor saw and hand saw blades. If the blade cuts through what it is supposed to be cutting (for example, asphalt) and cuts into road base the undercut segment protects the area where the segments join the blade body. It reduces the chances of the loss of a segment.

Undercut protection also reduces chances of blade biting or kicking back, which keeps the operator safer.

Being water wise

Water is always recommended for use with diamond blades. It significantly cools a blade, which increases it's life. Using water also reduces dust production. When cutting, the water combines with the dust to create an abrasive slurry, which assists with cutting. Too much water washes the slurry away and slows cutting, but too little can cause overheating. Cut back the water to "open" a glazed blade (ie allow the diamond to be exposed again, allowing efficient cutting to recommence) or when cutting through reo bars in concrete.

Note - In 2019, Worksafe WA specify "Uncontrolled dry cutting (ie dry cutting without local exhaust ventilation on-tool) is non-compliant and WorkSafe inspectors will take enforcement action where this practice is identified."

See more here