Re Tipping Core Barrels

Worn out or damaged core barrels do not always need replacement, and can often be can be re-tipped or missing segments replaced. Although we do not provide a re-tipping service, we supply diamond core bits so you can do it yourself. Our segments are designed for fast, free drilling in concrete and stone. The high quality polycrystalline diamonds ensure excellent drill speeds and footage.

Before re-tipping, check the following:

• Check the drive threads to see if they are damaged

• Check the barrel wall to see if it is too thin

• Check the outside diameter of the barrel for roundness or damage

If all these are serviceable, retipping is possible. Your barrel can be brazed by your local saw doctor or sharpening outlet, or any engineering workshop that offers brazing services.

If you are doing it yourself, you will need:

- Heat source

- Solder

- Flux

- Segments or crowns

- Magnetic tool holder

Heat source: 1,100° to 1,500° air temperature is required for brazing. Oxygen acetylene is the preferred traditional method. However, some of the new propane torches maybe sufficient heat - I have not used them but these are an easy, inexpensive alternative worth considering. A propane torch should be able to reach 1,995 degrees Celsius. MAPP gas is also used for brazing and soldering, where it has a slight advantage over competing propane fuel due to its higher combustion temperature of 2,020 °C. See an example Mapp torch here.

Solder: Use the right brazing rod. You need silver solder rods, cadmium free, with 39 - 40% silver.

My local plumbers supplier has to order these rods in for me, but they do sell them per stick.

One stick will usually do 10-20 segments, depending on your skill.

Flux: A fluxing agent is required for all brazing jobs. The flux removes oxides from the base material and prevents oxidation during the heating process, thus enablng the free flow of the solder.

I get it from a local plumbing supplier.

Segments and Crowns: Obviously, we supply premium quality segments and crowns.

You will usually need 2 segments per 1" of diameter plus 1 (to convert mm to inches divide by 25.4).

So a 127mm/5" barrel will usually have 11 segments and a 52mm/2" barrel should have 5 segments.

When replacing segments, just count how many you need.

For crowns, we just need an accurate diameter of the crown.

You will then need to pick the style of segment you want:

Turbo - long lasting in reinforced concrete

Crown - single piece segment from 14mm to 50mm only. See sizes and pricing at bottom of this page.

Now choose the segments (all prices include GST):

| Radius/inch | Coverage | Turbo (L x W x H) |

Price each |

| 2" | 50mm to 62mm | 24 x 3.5 x 10.5 | $6 ea |

| 2.5" | 63mm to 68mm | 24 x 3.5 x 10.5 | $6 ea |

| 3" | 69mm to 95mm | 24 x 3.5 x 10.5 | $6 ea |

| 4" | 96mm to 115mm | 24 x 3.5 x 10.5 | $6 ea |

| 5" | 115mm to 150mm | 24 x 4.0 x 10.5 | $7 ea |

| 6" | 151mm to 180mm | 24 x 4.0 x 10.5 | $7 ea |

| 8" | 181mm to 250mm | 24 x 4.0 x 10.5 | $7 ea |

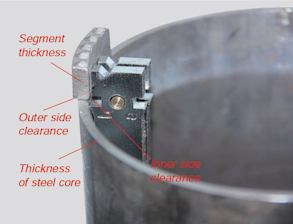

Magnetic tool holder: Also sold by UDT. Because the segments are usually 4mm thick and a barrel might be 2mm thick, this tool gives you the offset required when brazing your segments onto the barrel. One magnetic holder for each segment (as shown below) means you can braze all segments on without stopping to set up the next segment. $25 each incl GST.

How to Re tip:

Before re-tipping, check the following:

• Check the drive threads to see if they are damaged

• Check the barrel wall to see if it is too thin

• Check the outside diameter of the barrel for roundness or damage

Wear suitable personal protective equipment - safety glasses (tinted or sunglasses when brazing), hearing protection when grinding, gloves, long sleeve shirt etc.

Remove remaining segments if replacing all segments (use heat and pliers to melt the solder), otherwise check existing segments if replacing lost segments only.

Carefully clean the barrel with an angle grinder.

Gently clean the bottom and end surfaces of the segments a little with a 100/120 grit grinding wheel. Try not to expose any diamonds as this will reduce the strength of the brazing, possibly with the risk of segment loss.

Add flux to the brazing surfaces of the segments and the barrel and let dry.

Check the thickness of the segments and put your brazing magnet tools on the inside of the core. Choose the magnet setting so that the segment clearance on the outside will be about twice the clearance on the inside. This normally means using a 0.5mm magnet clearance when the difference is up to 1.5mm between segment and core thickness, and 0.75 mm on all other dimensions.

However, when coring very abrasive materials (like natural limestone or asphalt) increase the clearance one step on the inside, but never more than to 50/50 clearance.

Note, on very thin segments it may be impossible to get double the clearances on the outside, but never make the inside clearance larger than that of the outside clearance.

Start brazing by gently warming up the core under the segment and continue working with the flame sideways and up and down over the whole segment. Never keep the flame still and never use too hot a flame. Make sure the whole segment is warmed up and gets the same light red colour all over.

Add silver solder and continue warming until the solder melts and spreads. The silver solder should be melted by the heat of the metal pieces being joined, not by direct contact with the flame of the torch.

Continue to the next segment and repeat the brazing until all segments are brazed.

Check each brazing carefully. If any brazing does not look good, braze again!

Crown Prices (all prices include GST):

( All to suit reinforced concrete. Turbo style)

| Diameter/mm | Thickness, height/mm | Price |

| 12 | 2.0 x 10.5 | $14 each |

| 14 | 2.0 x 10.5 | $14 each |

| 16 | 2.5 x 10.5 | $14 each |

| 18 | 2.5 x 10.5 | Sold out |

| 20 | 2.5 x 10.5 | $15 each |

| 22 | 2.5 x 10.5 | $15 each |

| 24 | 2.5 x 10.5 | $16 each |

| 25 | 2.5 x 10.5 | $17 each |

|

26 |

2.5 x 10.5 | $18 each |

|

28 |

2.5 x 10.5 | $19 each |

|

30 |

2.5 x 10.5 | $22 each |

|

32 |

3.0 x 10.5 | $24 each |

|

35 |

3.0 x 10.5 | $25 each |

|

37 |

3.0 x 10.5 | $27 each |

|

38 |

3.0 x 10.5 | $27 each |

|

40 |

3.0 x 10.5 | $30 each |

|

42 |

3.0 x 10.5 | $31 each |

|

45 |

3.0 x 10.5 | $32 each |

|

50 |

3.0 x 10.5 | $40 each |

Prices correct as of 1/9/25 but subject to change.

Please see my Contact page for Australia wide delivery information.

Disclaimer: the information on this website is provided in good faith and believed to be reliable and accurate at this time.

However, the information is provided on the basis that the reader will be solely responsible for assessing the information and its veracity and usefulness. UDT shall in no way be liable, in negligence or howsoever, for any loss sustained or incurred by anyone relying on the information, even if such information is or turns out to be wrong, incomplete, out-of-date or misleading.

Address:

Unit 9, 84 Barberry Way

Bibra Lake WA 6163

Christmas 2025 Closure:

Close: Fri 19/12/25 at 3.30pm

Open: Tues 6/1/26 at 8.00am

Jan 2026 trading hours:

Tues, Wed & Thurs only, 8.00am to 4.00pm.

Normal trading after 3/2/26.

(ie Tues to Fri, 8.00am to 4.00pm)