Choosing the right diamond blade

If you select and use your diamond blades correctly, they will provide a good working life, great cutting speed and value for money.

Similarly, if the wrong blade is selected or it is misused, then you will lose money by damaging the blade. Or it will wear out very quickly, or not cut adequately.

There are many factors to consider when choosing which UDT diamond blade to purchase. They include:

The Price

For frequent use and larger jobs, it is better to choose a more expensive Premium Series diamond blade as they will deliver a longer life and a lower cost per linear metre of cutting.

However for occasional use and smaller tasks, it is quite often acceptable to choose from the lower priced Trade Series diamond Blade.

Quality and Size of Saw

- It is all based around the horsepower and RPM of the tool being used to complete the task. Diamond blades are rated to match the RPM of the saws and grinders.

High speed handheld saws and high speed cut-off saws need blades that are rated at higher RPM. Electric wall chasers need different blades from petrol powered ones. - Check both aspects of your machinery prior to choosing the product to suit. This ensures not only value for money, but also more importantly SAFETY.

The Material Being Cut

It is most important to correctly identify the material you are going to cut prior to choosing a Diamond Blade. This has a major effect on the cutting speed and life of the Diamond Blade.

Most materials fall into four categories: Hard, Medium to Hard, Medium to Soft and Soft.

The harder the material being cut, the softer the bond holding the diamonds needs to be. This allows the bond to wear and exposes the diamonds to cut the product and releases the diamond before it glazes over and makes the blade useless.

Conversely, when cutting soft materials, it is important to have a strong, hard bond that holds the diamond segments and increases the life of the blade.

Many people choose the hardest blade and believe it will cut everything. This is a false belief as hard bonded blades will not cut hard products!

As a general rule, determine the material which will be cut most often, or the material for which blade performance is most important.

If a blade is to be used to cut more than one material (for example, asphalt and concrete) determine which material will be cut the most often and buy a blade suitable for that material.

Types of Blades

Segmented blades have wider gullets (space between the segments) to help cool the blade and extract dust. They also helo prevent cracks developing when used in tough conditions.

This style of blade offers the fastest cutting speed, but are the roughest cut, with some chipping. The more abrasive material you are cutting, the wider the slot can be.

Segmented blades with narrow slots are generally for marble and granite, while keyhole shaped slot blades tend to be for general purpose.

These blades are usually in medium to hard bonds, and are durable with a long life.

Segmented blades are ideal for marble or granite slabs, concrete, reinforced concrete, asphalt and all building materials.

They are available from us in a wide range of diameters and particularly dominate the 12"/350mm diameter and larger market. These blades are commonly used with masonry saws, concrete saws, and circular saws.

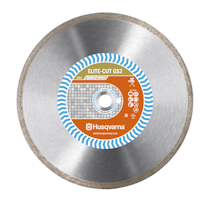

Continuous rim blades produce a good quality finish and longer life rather than segmented blades. They are used for wet cutting to cool down the blade and flush out debris and prevent dust. They generally have softer bonds for cutting hard materials such as tile, porcelain, granite, stone, glass, and other materials that can chip easily. The flat, continuous edge means there are no shocks against the material that could create chips in the cut edge. This type of blade is particularly suitable for tiles that need a perfect finish.

These blades are most commonly available in 4"/100mm to 14"/350mm diameters. The smaller, 4"/100mm to 5"/125mm diameter blades are often used in hand-held grinders, while the larger sizes are often used with circular saws and tile saws.

The J slot design is a variation of the continuous rim blade. It has "J" shaped slots around the edge of the blade to help dissipate heat for increased durability, extended blade life, and faster cutting speeds.

Turbo blades suit have softer bonds, so suit extremely hard materials, as they are more aggressive. Turbo blades feature a continuous rim with an edge that is serrated. This corrugated continuous rim gives smaller shocks to the workpiece when tackling the hardest tiles and building materials.

These blades are typically available in sizes that range from 4"/100mm to 12"/300mm diameters. They can be used in grinders, circular saws, and tile saws to cut a variety of materials including tiles, stone, marble, granite, masonry, and other hard building materials

Try to Avoid:

General Purpose blades - are a budget blade that tends to be at the cheaper end of the price range, but maybe okay for a handyman or light user.

Normally a general purpose blade would have segments that are of medium hardness, which means that it is suitable for cutting a range of building materials.

But they would not be very good for hard or abrasive materials like asphalt or limestone, causing them to wear very quickly.

Sintered blades - Sintering is a cheaper manufacturing process and is generally considered to be not as secure as laser welded blades for holding segments on the blade. If the blade gets hot, segments can come off, which is extremely dangerous, as well as ending the life of the blade. Sintering tends to be used on cheaper blades, so always look for laser welded blades.

Diamond blade cost is usually a minor factor in the overall cost of the job - labour and overhead costs are usually much greater.

Therefore it is important to select a diamond blade that can provide the best performance and productivity, not just the lowest blade cost.

What Blade Do You Need For Cutting?

We always recommend discussing your requirements with us, as there are many variables to diamond blade selection. But here is an indication of product specific blades we stock and sell.

Asphalt is highly abrasive and can wear blades extremely quickly. If cutting a lot of asphalt always use a United Diamond Tools black blade.

Green concrete is concrete that has set but not fully hardened or cured. Full hardening may take up to months to occur. Green concrete is also highly abrasive, so use a United Diamond Tools' black blade, or early entry blades for use on soff cut saws.

Sandstone and natural limestone is not as abrasive as asphalt, but still use a United Diamond Tools black blade.

If it is reconstituted limestone, I recommend a white blade.

Concrete, reinforced concrete, concrete kerbs and pipes as well as concrete pavers require a United Diamond Tools white concrete blade.

If you are regularly cutting a combination of asphalt, limestone and concrete I would recommend using a grey UDT Combi concrete/asphalt blade.

The grey will cut perfectly on asphalt and limestone and will be good on unreinforced concrete, making it ideal for customers cutting roads, kerbs and footpaths.

Wall chasing - we have a special range of blades in various diameters specifically designed for electric and petrol wall chasers.

Exposed aggregate is best cut with our white concrete blades, especially if you have exposed aggregate pavers.

Clay pavers cut with a brick saw requires a United Diamond Tools silenced blue blade. We also have unsilenced blue blades, although a concrete blade will often be sufficient.

Ceramic and porcelain paving is extremely hard and very brittle. Using a hand-held cut-off saw can be tricky, so a tile or brick saw is much better.

Segmented blades cause the pavers to chip or shatter. Even specific stone blades may cause chipping and flaking of the very hard surface.

Use our Ultra Thin Blades, or our specially formulated Super Turbo blades, for best results.

Porcelain is manufactured using very special porcelain clay that is fired at very high temperatures to create an exceptionally hard tile with almost zero water absorption.

'Ceramics' is general term that includes terracotta, stoneware and earthenware as well as porcelain. Porcelain is a ceramic, but not all ceramics are porcelain.

Alumina ceramic and silicon carbide is used in wear plate manufacture. As a ceramic, it needs a similar blade to porcelain. However, alumina ceramic is often mounted with rubber, so cutting becomes very complicated. Contact United Diamond Tools for advice on our range of blades that will cut without chipping in this complex application.

Granite is very hard, so requires a blade with a softer bond like the UDT pink series. These blades will wear out extremely quickly if used to cut any of the more abrasive materials above.

Refractory brick and marble are both very difficult applications, and these require specialist blades for cutting without cracking or chipping. Contact UDT for a quote on the right blade.

Fibreglass and glass need our electroplated tile saw blades.

Rescue blades - Vacuum brazed blades will usually cut a wide variety of material including concrete, masonry, steel, various irons, plastic, tile, wood and glass. They are also used to cut rail line. The Fire Brigade will use them on "rescue" saws, so they are often are called rescue blades. They perform well in dry applications, but the blade will last longer if water is used with them.

Core Sample blades are widely used across the Western Australian Goldfields and in the mining industry for cutting core samples. We carry many specific core cutting blades for cutting very hard materials.

| Material | Abrasiveness | Bond | UDT Blade |

| Limestone, sandstone | Extremely | Hard | Black |

| Asphalt | |||

| Green Concrete | |||

| Concrete pavers/pipes/kerbs | Very | Medium | White |

| Reconstituted limestone | |||

| Concrete Slabs, precast | |||

| Reinforced Concrete | |||

| Clay Bricks & Pavers | Abrasive | Medium/soft | Blue (or white on cut quicks) |

| Granite & hard clay bricks | Low | Soft | Pink |

| Alumina/Ceramic | Low | Soft | Specific range of blades |

| Refractory applications | Low | Soft | Specific range of blades |

| Ceramic | Low | Soft | Continuous rim ceramic |

| Porcelain | Low | Soft | Continuous rim porcelain |

| Marble | Low | Soft | Specific blade |

We always recommend discussing your requirements with us, as there are many variables to diamond blade selection. But here is an indication of product specific blades we stock and sell.

Disclaimer: the information on this website is provided in good faith and believed to be reliable and accurate at this time. However, the information is provided on the basis that the reader will be solely responsible for assessing the information and its veracity and usefulness. UDT shall in no way be liable, in negligence or howsoever, for any loss sustained or incurred by anyone relying on the information, even if such information is or turns out to be wrong, incomplete, out-of-date or misleading.